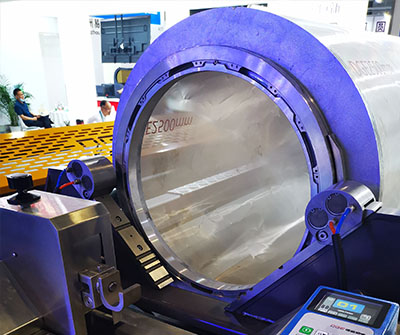

7280A Series: (High-Speed Type) Magnetic + Squeegee Universal Type Rotary Screen Printing Machine

Rotary screen printing machines are the most mainstream continuous printing equipment in the textile industry. Their core feature is the use of a hollow, cylindrical nickel screen to transfer printing paste, hence the name "rotary screen". They perfectly balance production efficiency, printing quality and production costs, and are particularly suitable for large-scale textile printing production.

The 7280 series has undergone five upgrades and is highly capable of meeting the requirements of double-sided penetration printing technology.

Technical parameters

1.Printing unit | |||||||||||||||||

Model | 7280A(High Speed Type) | ||||||||||||||||

Nominal width(cm) | 180 | 200 | 220 | 240 | 260 | 280 | 300 | 320 | 340 | ||||||||

Effective printing width(cm) | 162 | 185 | 205 | 225 | 245 | 265 | 285 | 305 | 325 | ||||||||

Standard colors | 4/6/8/10/12/14/16 | ||||||||||||||||

Repeat size(mm) | 577、640、820、914、1018 | ||||||||||||||||

Printing varieties | Knitted fabric, woven fabric | ||||||||||||||||

Printing speed | 4~ 100m/min | ||||||||||||||||

Printing type | magnetic type + scraper type(any combination) | ||||||||||||||||

Alignment accuracy | ±0.1mm | ||||||||||||||||

Transmission mode | Guide belt drive: Physis servo motor | ||||||||||||||||

Printing unit: Independently driven by Europe servo motor | |||||||||||||||||

Machine operation | Left/right hand (It is decided by the customer) | ||||||||||||||||

2.Feeding cloth unit | |||||||||||||||||

Model | T2181 | T2280 | T2381 | T2480 | H2181 | H2280 | |||||||||||

Type | woven fabric | woven /knitted fabric | woven /knitted fabric | knitted fabric | woven fabric | woven /knitted fabric | |||||||||||

3.Dryer unit | |||||||||||||||||

Model | S3013 | S3023 | S3033 | S3055 | |||||||||||||

Dryer sections | 4/5 | 5 | 4/5 | 7/8 | |||||||||||||

Applicable fabric | Thin fabric | Thin fabric | Thick fabric | Thick fabric | |||||||||||||

Speed | 5~100m/min(50HZ) | ||||||||||||||||

Dryer temperature | 80℃~180℃ | ||||||||||||||||

heat source | Heat transfer oil/Steam/natural gas (standard: Heat transfer oil) | ||||||||||||||||

4.Power configuration | |||||||||||||||||

Power supply | AC3-380V±10﹪,50Hz | ||||||||||||||||

Total power | 160 KW | ||||||||||||||||

Compressed air | 0.6~0.8MPa | ||||||||||||||||

Water source | 0.2~0.4MPa | ||||||||||||||||

|  |

Advantages of DGE rotary screen printing machine

● High-speed and high-precision printing, with the maximum printing speed reaching up to 100 meters per minute

● The printing method can be a combination of magnetic and squeegee type

● Industrial fieldbus data transmission, remote fault diagnosis and monitoring

● The guide belt drive adopts a European integrated servo motor and a precision reducer

● Double-beam adjustable printing unit, easy to maintain and clean

● Double-sided digital independent operation control console for both the driver and the deputy

● European brand servo motors and precision planetary gear reducers

● High efficiency and high speed: It adopts a continuous production mode and has an extremely fast running speed, usually reaching 50-100 meters per minute, which is much higher than that of flat screen printing machines.

● Suitable for mass production: It is the most economical choice for handling large-scale orders. The greater the ou tput, the lower the cost per meter.

● Multi-color set capability: One machine can be equipped with 8 to 16 (or even more) printing units, capable of printing richly colored patterns in one go.

● Stable printing quality: With a high degree of automation and precise pattern alignment, it can ensure the consistency of color and pattern throughout the entire batch of fabrics, with good reproducibility.

Wide range of applications

It can be used on various fabrics, such as cotton, chemical fibers, silk, knitted fabrics, etc., and is especially good at printing continuous cycle patterns, geometric shapes and ground cover patterns.

The production cost is relatively low: During mass production, both the cost of making the nickel screen and the cost of slurry consumption have advantages.

Applicable scenarios

● Clothing fabrics: such as printed cotton fabric, polyester fabric, etc.

● Home textile fabrics: such as curtains, bed sheets, sofa fabrics, etc.

● Large-scale orders: It is the main production equipment for brand clothing and home textile suppliers.

24-Hours Hotline

24-Hours Hotline